●Film Coating Agent/ Phosphating Agent

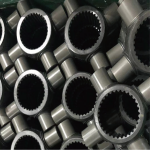

■ Iron Phospating Room temperature and heating codition are both fine, realizing phosphorus removal through soaking or spaying and forming colorful film. Fit for kinds of paint (iron series is not as good as zinc), especially for electrophoresis and electrostatic spraying. ■ Zinc Phospating Fast low slag phosphating technology at low and room temperature, obvious energy saving and consumption reduction, easy to use, suitable for paint coating, electrostatic powder coating, electrophoretic coating. ■ Zinc manganese nickel phosphating High P-ration and corrosion resistance, fast film forming at medium-low temperature. Suitable for cathode electrophoresis, painting, plastic spraying and other bottom coating, also can be used with rust-proof oil. ■ Medium temperature zinc and calcium phosphating agent Environmentally friendly, nickel free and strong corrosio nresistance, 15minutes to 40 minutes for copper sulfa tedrip test without hang slag and surface conditioner ne eded, especially avoiding the problem of chromatic aberration (popular problem when phosphate the steel pipe) ■ Black manganate and nickel free phosphating solution under medium temperature High degree of finish, excellent corrosion & wear resistance, extraordinary temperature resistance and environmentally friendly. Widely used in military industry, automobile, motorcycle,engineering machinery,engine, gearbox, bearing, piston bushing, and fastener industry etc.. Anti-wear performance is beyond the standards of automobile of France's PSA Peugeot Citroen automobile company (B15 3100). The crystal of phosphating film meets the strictest standard of Europe and the United States. Crystallization of manganese phosphating not only can realize 20-minute copper sulfate drip test, but also could resistant to the high temperature of 800 centi-degrees without discoloration, falling off and pulverization. The biggest differentiation is that iron ion won't rise eliminating additional removal process without the hang slag, which improve production efficiency by more than 50%, and save energy at least 60% above. Our product has passed technical appraisal of PLA General Armament Department whose specifications are included into Military Standard Quality Management System. ●Chromium free passivating agent ■Chromium free passivating agent for aluminum alloy Nano level ceramic film formed on the surface of the aluminum alloy with high corrosion resistance, and no need the process of nitric acid bright dipping process and washing after passivation which greatly reduce the wastewater emissions and can realize standard discharge after the simple treatment. The nanoscale ceramic coating can resistant high temperature and reach more than 1500 hours in salt spray without obvious pitting corrosion especially after 2600 hours. ■ Room temperature chrome-free passivating ( zirconium-based treatment) agent Replacing phosphating,without phosphorus and any heavy metalions. No need to surface conditioning and accelerator. 3-5 minutes to form film almost without slag. Can process steel, aluminum alloy, magnesium alloy, and galvanized products at the same time,solving the problem of waste water treatment. The binding force with paint, electrostatic powder coating, electrophoretic coating is perfect. Same performance as nickel zinc manganese phosphating film in salt spray test, and after cathodic electrophoretic painting, the cross grid surface resists more than 1,200 hours in salt spray test. The other technical specifications are basically the same as phosphating film, and even exceed phosphating film, which meets the technical requirements of automotive cathodic electrophoretic painting. ■ Chromium free passivation ceramic film for titanium alloy Salt spray test performance meet and exceed the resistance level of titanium alloy itself, suitable for precoating and titanium alloy corrosion quick repair in environment similar as South China Sea. A variety of film coating technologies can fully meet the technical requirements of titanium alloy surface treatment. ● Stainless steel passivating agent Environmentally friendly and chromium & nitrogen free, reach more than 1000-1500 hours in salt spray test. The oxalate conversion film used for cold extrusion and drawing of stainless steel. ● Silane Slag-freee, phosphorus-free and heavy metals free, no need of surface conditioner and passivation and only room temperature needed. Support multi-metal treatment.Excellent energy saving and eviromental performance.

|